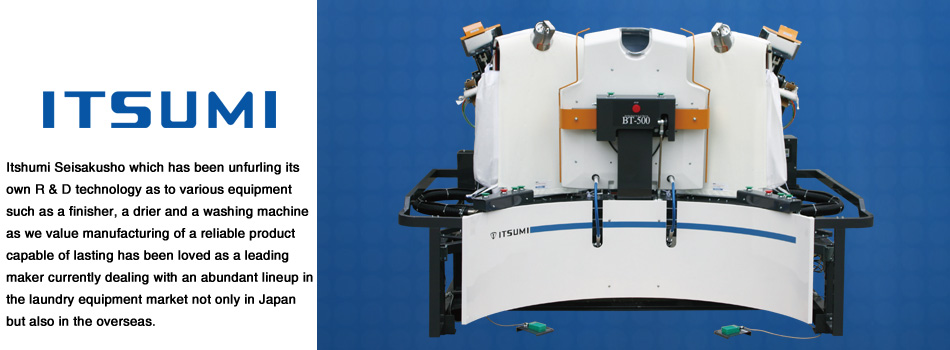

Itsumi Seisakusho started its operation as R & D company of a press machine in 1951 and we are producing laundry equipment destined not only for Japan but also for the world market based on the total technology dealing with various finishers, driers and washers.

Itsumi is a leading company of a laundry equipment based on reliable technology.

We hereby would like to introduce Itsumi Seisakusho's product lineup such as a business use washer, various finishers and a drier.

-

2014.10.07

Single Body Press/ BT-70-J Saver

Single Body Press/ BT-70-J Saver, a shirt finisher was put on sale.

This product achieved reduction in finishing process time and long life deriving from inheriting and refining an advantage of BT-50-J popular for high cost performance.

(→For further information on BT-70-J Saver, click here)

-

2013.12.24

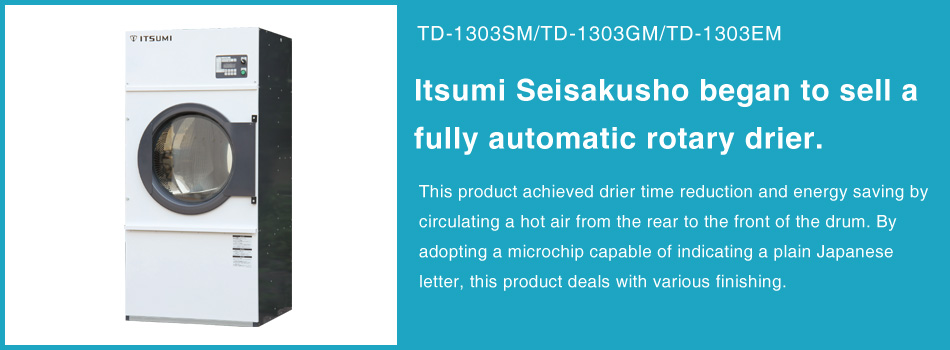

Full Automatic Rotary Drier TD-1303SM (steam), G (gas) and E (electricity)

Itsumi Seisakusho began selling Full Automatic Rotary Drier TD-1303SM (steam), G (gas) and E (electricity) on December 3, 2013.

This product achieved reduction in drying process time and energy saving by circulating a hot air from the rear to the front of the drum. By adopting a microchip capable of indicating a plain Japanese letter, this product deals with various finishing. -

2013.11.22

Fashion Pants Topper TO-550AS

Itsumi Seisakusho began selling new Fashion Pants Topper TO-550AS on November 4, 2013.

This product achieved high efficiency and quality of finishing by means of an automatic tuck equipment with a new function.

Accordingly TO-350AS will be supplied on build-to-order manufacturing basis. -

2013.06.27

Information on our homepage renewal

Thank you very much for your attention to Itsumi Seisakusho.

We are hereby pleased to inform our homepage renewal.

Please keep paying attention to our homepage as before, as we will make an effort in enhancing its contents. -

2012.10.03

New general catalog

New general catalog including Itsumi Seisakusho's steam box was provided

→ In case of downloading the catalog, click here.

-

2012.10.01

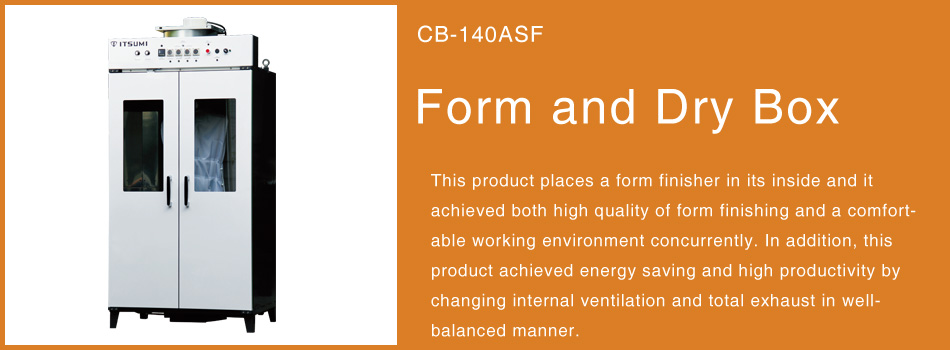

Form & Dry Box CB-140ASF and Dry Box CJ-140S

Itsumi Seisakusho began selling Form & Dry Box CB-140ASF and Dry Box CJ-140S on October 1. This product places a form finisher in its inside and it achieved both high quality of form finishing and a comfortable working environment simultaneously. In addition, this product achieved energy saving and high productivity by changing internal ventilation and total exhaust in well-balanced manner. -

2012.09.13

Steam & Dry Box CB-50S

Itsumi Seisakusho began selling Steam & Dry Box CB-50S on August 5, 2012. This product inherited an advantageous function, excluding vibration, and incorporated it into a compact body.

By adopting a plain and easy to use new controller, its working efficiency also got higher. Accordingly sale of CBX-5 was discontinued. -

2012.06.08

White Coat Double Body Press BT-600-J and Double Collar Press SC-500AS

Itsumi Seisakusho began selling White Coat Double Body Press BT-600-J having a unique dummy mover and Double Collar Press SC-500AS capable of simultaneous double collar press on April 11.

These products achieved space saving, energy saving and significant time reduction by integrating a conventional four-piece set into two units. -

2012.03.01

Full Automatic Rotary Drier TD-1005S, TD-1005G and TD-1005E

Itsumi Seisakusho began selling Full Automatic Rotary Driers TD-1005S (steam), G (gas) and E (electricity) on January 5, 2012.

This product achieved reduction in drying process time and energy saving by circulating a hot air from the rear to the front of the drum.

These products also achieved working efficiency improvement by adopting a plain and easy to use timer and thermostat. -

2011.06.15

Steam & Dry Box CB-100S

Itsumi Seisakusho began selling Steam & Dry Box CB-100S on July 15, 2011.

This product achieved working efficiency improvement by means of improvement of finishing function by steam injection and static drying function by massive air flow in addition to a user-friendly heat insulation frame and adoption of a plain and easy to use new controller.